Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

How to test Mohs hardness scale of wear resistant ceramics

To be excellent wear abrasion resistance, wear resistant ceramics need have high hardness. And Mohs hardness scale is an international standard to evaluate alumina ceramics’ hardness.

It was proposed by the German mineralogist Frederich Mohs in 1824. And usually we use the scratched method to test the hardness of unknown mineral. The scratched method is use a mineral whose Mohs hardness scale is known to scratch the surface of the tested mineral, then compare their scratch. If the surface of the tested mineral is scratched, the hardness of it is less than the known mineral; if the surface of the known mineral is scratched, the hardness of the tested mineral is greater than the known mineral. And these are ten minerals whose Mohs hardness scale is known :

| Mineral's name | Mohs hardness scale |

| Talc | 1 |

| Gypsum | 2 |

| Calcite | 3 |

| Fluorite | 4 |

| Apatite | 5 |

| Feldspar | 6 |

| Quartz | 7 |

| Topaz | 8 |

| Corundum Ruby or Sapphire | 9 |

| Diamond | 10 |

To test the Mohs hardness scale of high alumina ceramics tiles, you only need :

1. Place a piece of tested alumina ceramics tiles on a rigid support.

2. Selection of different Mohs standard ore to scratch the surface of ceramic tile.

3. Compare the scratch of ceramic tile with the ores and repeat 2rd step until the surface of the alumina ceramic tile is scratched.

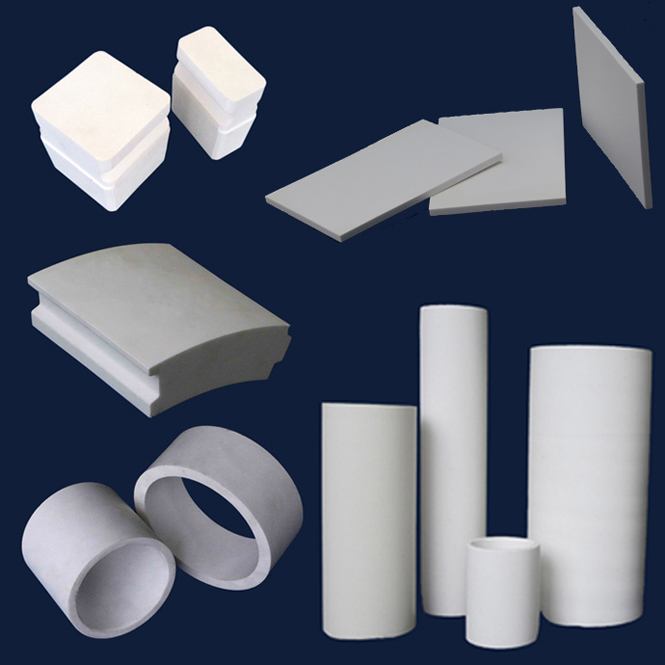

Pingxiang chemshun ceramics co.,ltd is a professional manufacturer of 92%95% alumina ceramics, ZTA ceramics with the good character of strong hardness (9 Mohs hardness scale), strong abrasion resistance and impact,corrosion resistance, excellent heat resistance (up to 1500centi degree) and it’s easy to install.

Chemshun Ceramics can design and produce the ceramic tile liner, weldable ceramic tile, alumina curved tile foe pipe and alumina tube products for different equipment and industries. We have the ability to design and make the CAD drawings according to the client’s wear application. Once you need more information welcome to contact with us by email office@chemshun.com or calling us +86-799-6790781, 0086-158-7995-7696 And we also welcome you to visit our website : www.chemshun.com.