Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

How to choose ceramic grinding media for your mill

The output of miner resource has decreased a lot,the inferior quality of ores, the complicated composite of ores,directly ores exploration difficultly,these factors lead to the high requirement standard of our fine grinding process accurately,generally the common ball mill is widely used in many miner industries and the high chrome steel balls occupy main position among the ceramic grinding media,but this combination will generate the low grinding efficiency,the grind fitness is not up to the expected goal and the requested quality of ores can keep 53-55%.

With the increased requirement of the powders in the miner and non-metallic field as well as the low cost, this phenomenon asks a large grind mill which has high grind efficiency ,and save the energy to get the exact grinding fitness.

In this trend, 10000L grind mill is necessary to gold, silver, copper, iron, molybdenum, nickel mine, meantime the small size of ceramic grinding media is basic in wet grinding process for these types of mills such as ball mill, horizontal mill, vertical mill etc.

Pingxiang Chemshun Ceramic Co.,ltd is Ceramic Grinding Media manufacturer. To meet the market requirement of different milling applications, Chemshun Ceramics developed a range of ceramic grinding media with broadest range of sizes and densities are available to suit both horizontal and vertically mills for fine & ultra-fine grinding, mixing and dispersing.

Here we could provide simple rule that ceramic grinding media matches its relevant mill type,but all ceramic grinding media options should be considered in the actual application with the professional technical engineers who is charge of the mills.

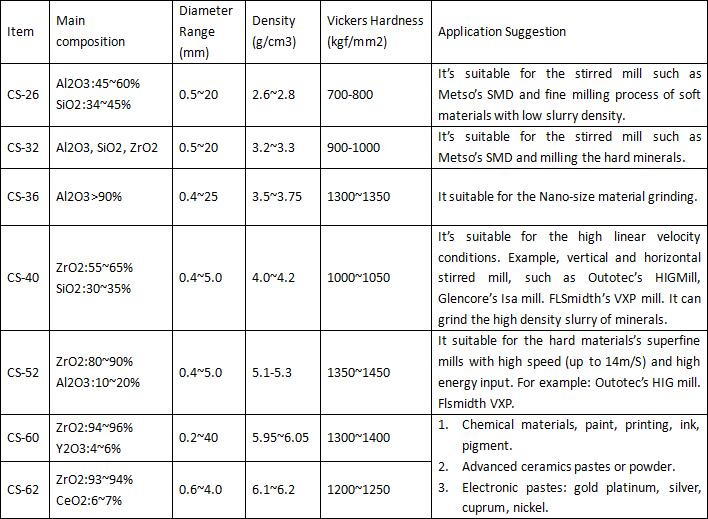

1)High-performance, Low-density ceramic grinding media: alumina silicate balls CS26 with unmatched economic and performance advantage in fine and ultra-fine grinding process of soft mineral materials with low slurry density.

2)High-performance, middle density ceramic grinding media: CS32, high alumina balls CS36, zirconia silicate balls CS40, which widely used in the grinding mill of mining and minerals and suitable for hard minerals, high density slurry of minerals. The series media improve cost efficiency of customer.

3)High-performance, high density ceramic grinding media: alumina toughened zirconia beads CS52, yttria stabilized zirconia beads CS60, Zirconia-Ce ceramic balls CS62 with the best grinding, mixing and dispersing efficiency. This zirconia-based grinding media is the optimum combination of efficient and cost-effective products to enhance productivity and quality.

If you have any interest, you can contact us by mail: office@chemshun.com or call us by the telephone : +86-799-6790781.