Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

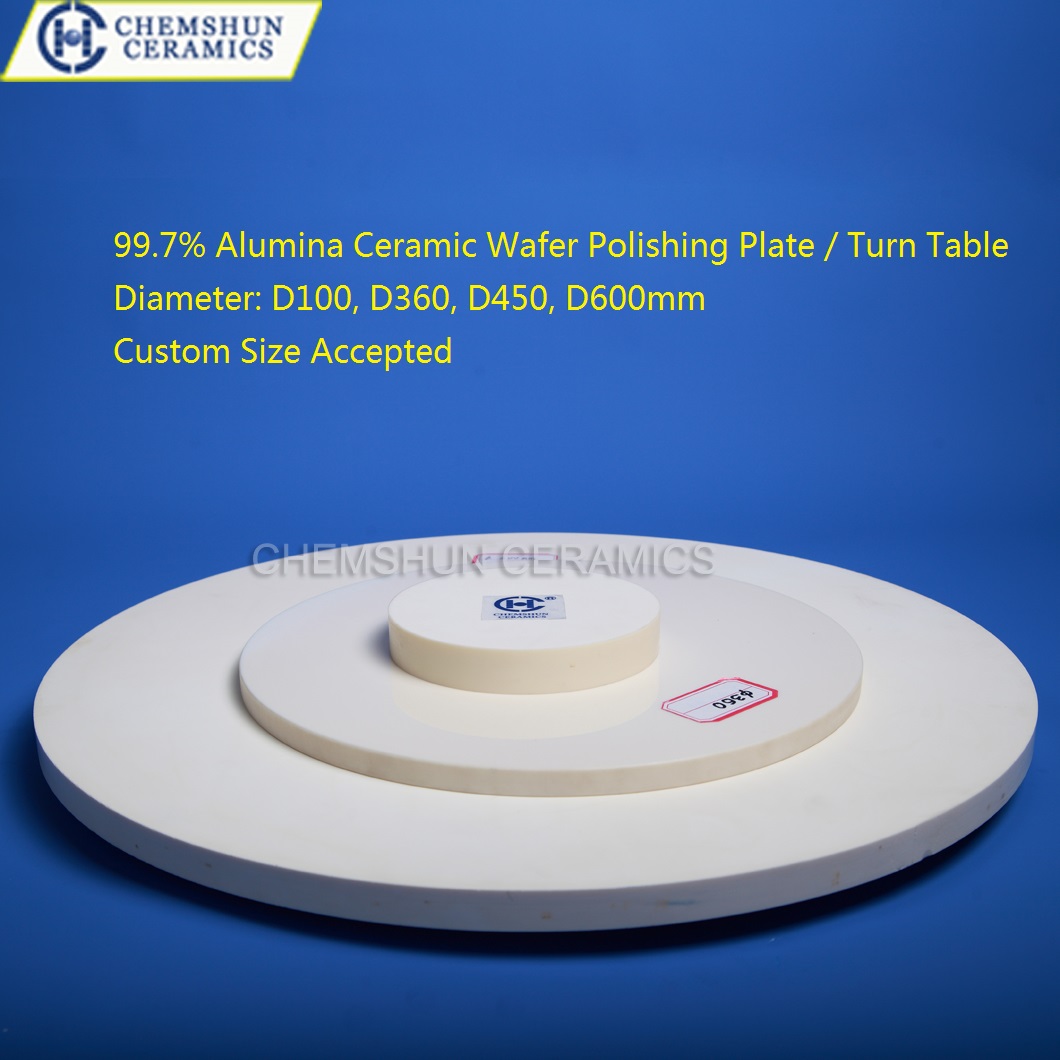

Semiconductor-----Silicon Wafer Polishing

Semiconductor----Silicon Wafer Polishing

Briefly talk about the steps of silicon wafer polishing as below :

In the first step, the front side of the silicon wafer is treated, an adhesive is coated on the back of the silicon wafer, the silicon wafer is adhered to the ceramic board, the corrosion layer on the front surface of the silicon wafer is removed, and the silicon wafer is separated from the ceramic board by using a spatula, and cleaned and removed For the adhesive on the back of the silicon wafer, use a thickness measuring device to measure the thickness of the silicon wafer.

In the second step, the backside of the silicon wafer is treated, an adhesive is coated on the front of the silicon wafer, the silicon wafer is adhered to the ceramic board, the corrosion layer on the back of the silicon wafer is removed, and the silicon wafer is detached from the ceramic board with a spatula, and cleaned and removed Adhesive on the front of the silicon wafer to measure the flatness of the surface of the silicon wafer, and use a thickness measuring device to measure the thickness of the silicon wafer.

In the third step, the front surface of the silicon wafer is finally trimmed, an adhesive is coated on the back surface of the silicon wafer, the silicon wafer is adhered to the ceramic board, the corrosion layer on the front surface of the silicon wafer is removed, and the silicon wafer is detached from the ceramic board with a spatula and cleaned Remove the adhesive and particles from the back of the silicon wafer.