Top articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- The reason of abrasion resistant ceramic tiles falling off when pasted on equipment

- Seven aspects of advantages & applications of alumina ceramic substrates

Latest articles

- High-purity 99.7% alumina ceramics helpful to semiconductor manufacturing technology

- Alumina Ceramic Grinding Balls: High-Efficiency Solutions for Industrial Grinding

- How to Select Suitable Wear-Resistant Ceramic Lining Tiles in the Mining Industry

- Advantages of Ceramic Rubber Composite Liners in Industrial Applications

- How to Install Alumina Ceramic Liners for Long-Lasting Adhesion?

- Welcome to EXPOMIN 2025

- 99% alumina bulletproof ceramics are the preferred materials for protective devices

- Alumina Ceramic Substrates:Characteristics,Advantages,Disadvantages,and Applications

- Why do alumina industrial ceramics wear out?

- Chemshun Ceramics Chinese New Year Holiday Notice

Your browsing history

How to Cut Alumina Ceramic Liner ?

Wear resistant ceramics as a popular wear resistant lining material are widely used in the industrial conveyer system. It's main component is 92% or 95% Alumina, α crystal phase with very high hardness. In the application process, we often find some area is no regular and the regular ceramics bricks for example150x100x13mm can not be used. To solve this problem,we need the cutting engineered ceramics, which shape and size are 100% meet the installed surface. How to cut wear resistant ceramics? Following us Pingxiang Chemshun Ceramics Co.,ltd, we share 2 cutting method with you.

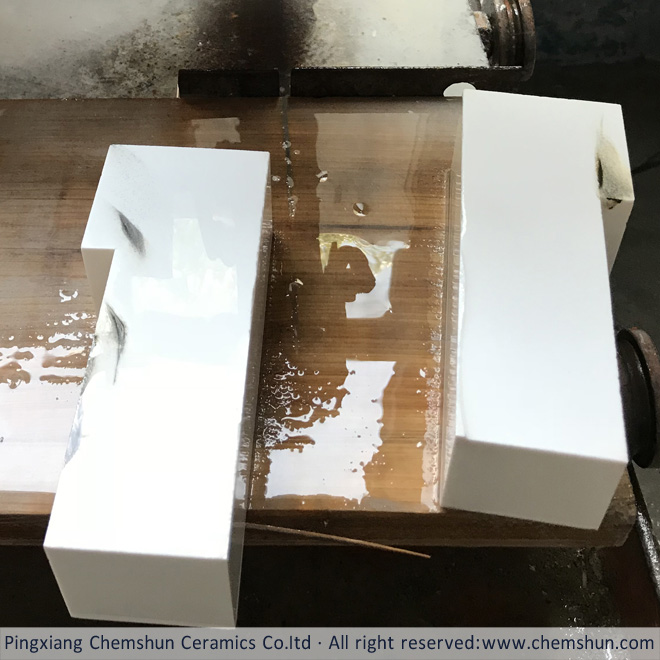

Cutting method 1: Finished wear resistant ceramics cutting

Tools: Cutting machine, Diamond Blade.

Advantage: This way can meet the flexible demand in your install or repair process. You can use it at your workshop.

Disadvantage: The cutting time is long because of the high hardness of alumina ceramics. The cutting surface should be easy.

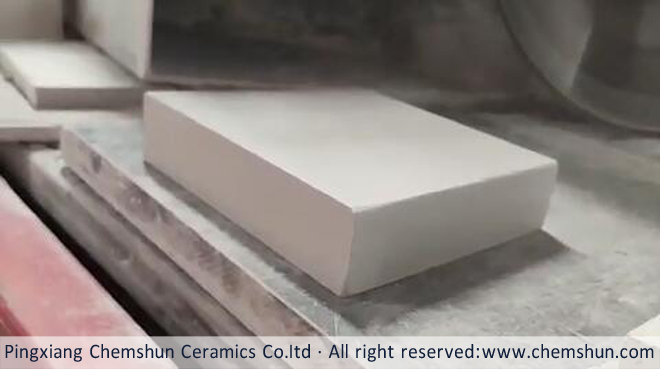

Cutting method 2: Semi-finished wear-resistant alumina ceramic cutting

Tools: Cutting machine, Carving Machine.

Advantage: More Shape More size engineered ceramics can be produce.You directly use the engineered ceramics and don't cut ceramics on site. Saving your install time and the install effect are perfect.

Disadvantage: The work finished only in the professional wear resistant ceramic factories have experienced engineers who know well the of CAD design and with the knowledge of ceramics and the application. This cutting made by the skilled workers.

The semi-finished ceramic products cutting are higher quality and efficiency than finished ceramic products. Chumshun Ceramics Team produce all type of wear resistant ceramic lining and provide professional engineering services. We have experienced engineer team, skilled workers and all kind of professional ceramic cutting /curving machines, we accept customization orders.

Chemshun main products are:

Wear-resistant ceramic tiles (weldable), alumina ceramic linings, ceramic tubes, ceramic elbow tubes, ceramic cylinder, hexagonal ceramic tile mat, etc. Also,we supply cutting blade and hand finished cutting machine.

Welcome to email us office@chemshun.com or calling us +86-799-6790781, 0086-158-7995-7696 and visit our factory or our website : www.chemshun.com to know more.