Current location: HomeCHEMSHUN News » Industry News

- Will The Yellowing of Alumina Wear-resistant Ceramics affect Product Performance? [09-20 02:26]

- 1. Decreased aesthetics After alumina wear-resistant ceramics turn yellow, their appearance no longer maintains the original whiteness or specific color, but presents a light yellow or darker color. This color change directly affects the aesthetics of the...

- Alumina ceramic pipes used for lithium battery transportation to ensure stable operation [09-16 16:03]

- Abrasion resistant ceramic pipes are used for lithium battery transportation, which is a common application scenario. alumina ceramic pipes are made of high-strength Al2O3 ceramic wear resistant materials, with high corrosion resistance and wear...

- Analysis and solution of welded wear resistant ceramic tile falling off [09-08 21:06]

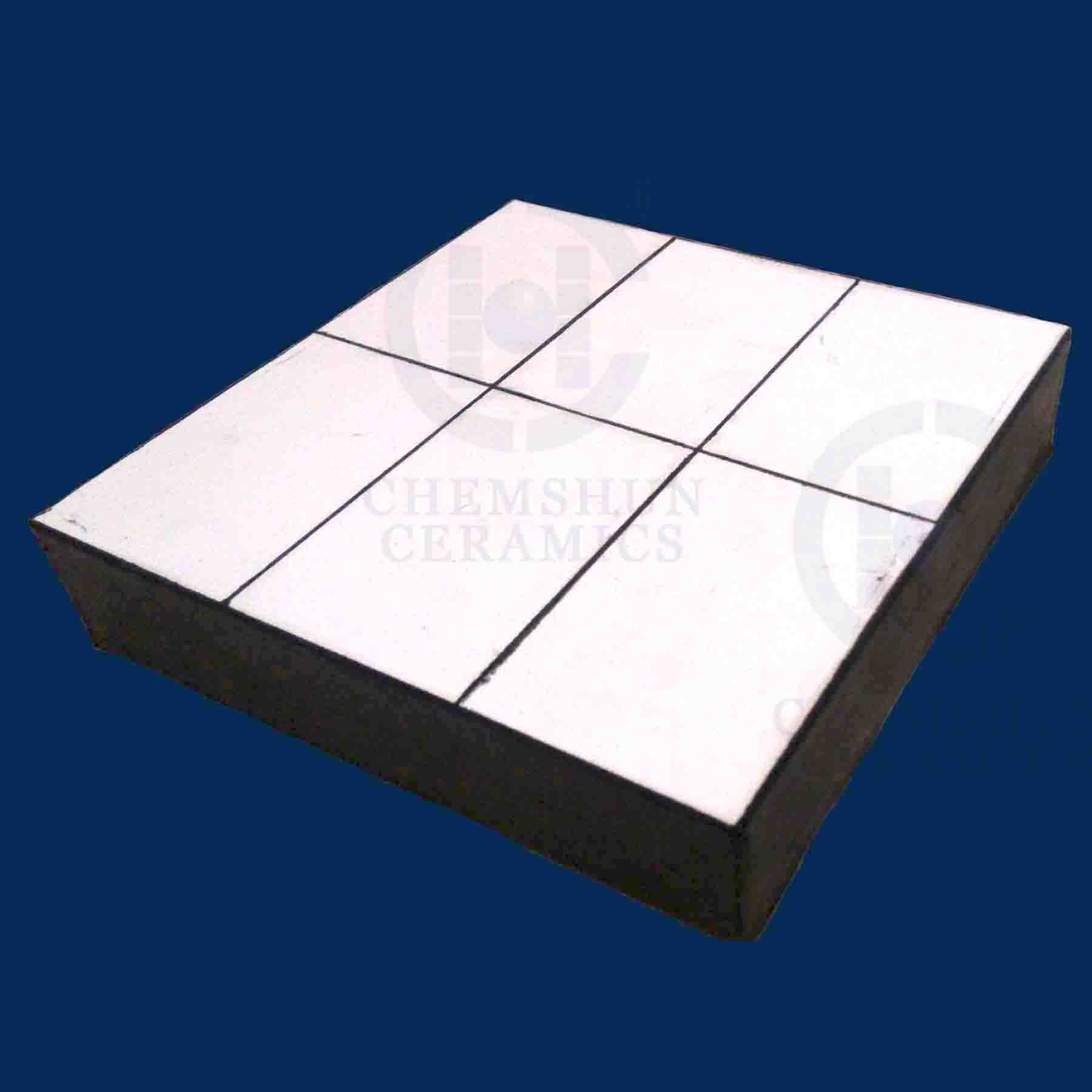

- Welded wear resistant ceramic tile liner play a vital role in various industrial fields, such as power plants, cement plants, etc. Their high wear resistance and long life can effectively protect equipment from wear. However, in actual applicati...

- Wear-resistant ceramics are used in cement industry [08-31 09:03]

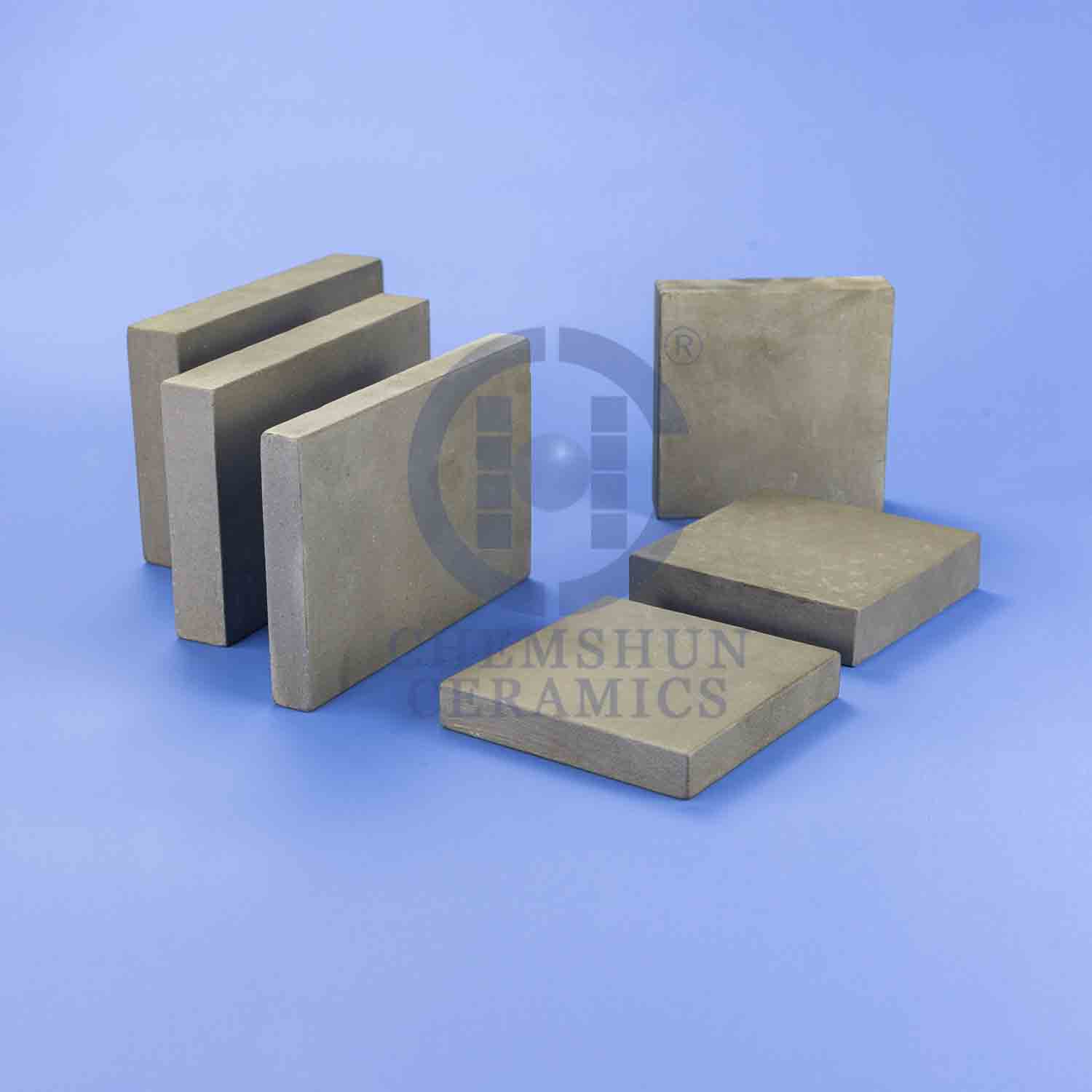

- Wear-resistant ceramics are widely used in cement industry. For example, wear-resistant ceramic sheets, wear-resistant ceramic pipes, ceramic balls, wear-resistant ceramic lining and other products are widely used in cement plants, power plants, mining and other industries, which often need to transport materials with certain wear.

- Alumina ceramic tiles are used in industrial equipment [08-26 14:31]

- Alumina ceramic plain tiles have excellent corrosion and wear resistant property and are ideal for use in transfer chutes, piping systems, hoppers, etc. Typical markets include grain, coal-fired power generation, mining, cement, and more.

- What should buyers pay attention to when choosing wear resistant ceramic liner [08-21 16:30]

- When choosing to use wear-resistant ceramic liner, it is necessary to consider its use environment and working conditions, as well as the size and aluminum content of the equipment. Here are some factors to consider:

- The mining industry can use high-strength alumina ceramic balls [08-19 16:49]

- The mining industry can use high-strength alumina ceramic balls. High strength alumina ceramic ball has the characteristics of high hardness, good wear resistance, corrosion resistance, good thermal stability, stable chemical properties, etc., so it is suitable for mine grinding. In the mine grinding process, the high-strength alumina ceramic ball can effectively reduce the contact area between the grinding medium and the ore, reduce the grinding power consumption, improve the grinding efficie

- Wear-resistant Ceramic Sheets are Used for Anti-wear Lining of Pipes [08-14 11:11]

- Wear-resistant ceramic sheet is an effective wear-resistant material, which has higher hardness and better wear resistance, and can be used as an anti-wear layer for various pipes. Its application areas include:

- Alumina Ceramic Cylinder for Vulcanized in Wear Ceramic Rubber Liner [08-09 07:49]

- Alumina ceramic is an important inorganic non-metallic material, which has the advantages of high strength, high hardness, corrosion resistance, impact resistance, high temperature resistance and so on. In industry, alumina ceramics are widely used in thermal power, mining, coal, steel, cement and other industries.

- High-purity Alumina Ceramic Wafer Polishing Plate [07-31 00:52]

- High-purity alumina ceramic features outstanding rigidity and excellent wear-resistance for wafer polishing and maintains good surface shape over a long period of time.

- Alumina ceramic tube - high quality wear-resistant ceramics [07-29 03:11]

- Alumina ceramic tube is a kind of tubular industrial ceramic product made of high quality alumina as raw material. It has the characteristics of high strength, high hardness, high wear resistance, corrosion resistance, good thermal stability, etc., is the ideal wear resistance, temperature resistance, anti-corrosion material.

- Wear-resistant ceramics solve the problem of wear in the mining industry [07-22 02:03]

- Wear problems in the mining industry can be solved by using wear-resistant ceramics. Wear-resistant ceramic is a kind of ceramic material with excellent wear-resistant properties, which has the characteristics of high hardness, high strength, corrosion resistance, high temperature resistance, etc., and is suitable for various working conditions.

- Wear-resistant ceramic tubes are used in the lithium battery transport industry [07-19 01:32]

- Wear-resistant ceramic pipes have good chemical stability, which can resist the corrosion of most chemical substances, including acids, alkalis, salts and other chemicals. This makes it particularly suitable for handling chemicals used in the production of lithium batteries, such as lithium salts and various organic and inorganic solutions.

- Wear-resistant ceramic rubber plate for port industry [07-17 03:01]

- Wear Resistant Rubber Ceramic Panels is made by a combination of wear resistant alumina ceramics (cylinders, hexagon, plates) vulcanized in resistant rubber base, some rubber plates can selectively with steel backing.Wear-resistant ceramic rubber composite panels have a variety of applications in ports, including but not limited to the following situations:

- Alumina ceramic ball - high hardness grinding medium [07-08 01:21]

- Alumina ceramic ball is a spherical grinding medium made of alumina (Al2O3) powder, usually used in ceramics, glass, metal and other industries. It has high hardness and high wear resistance, which can effectively improve processing efficiency and quality.

Contact Chemshun

TEL:+86-799-6790781

FAX:+86-799-6790785

Mail:office@chemshun.com

Factory 1 Address: Jilin East Road, Anyuan Industrial Area, Anyuan District, Pingxiang City, Jiangxi Province, P.R.China.

Factory 2 & Office Address: No.16, Jinguang Avenue, Anyuan Industrial Area, Anyuan district, Pingxiang City, Jiangxi Province. P.R.China.